2019-12-10

One Million Unique Parts Machined

STEP is a standard for product model data and IFC is a standard for building model data. Both are very widely supported by CAD, CAM and BIM systems.

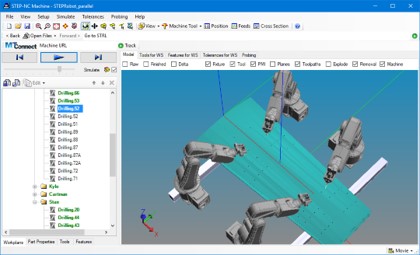

STEP-NC AP238 used to make 1,000,000 parts in 2019

- Argument won — STEP-NC is the machine control data for future aerospace.

- Boeing uses STEP-NC to machine parts for all its major airframes both single aisle and double aisle — even for satellites.

- Engineer who did the work promoted to Technical Fellow.

- Soon FAA is likely to want STEP-NC documentation for every machined part on an aircraft.

STEP AP242 Edition 2 is finished

- Every CAD system has an interface to read and write STEP.

- Edition 2 enables automatic measurement for on-machine CNC, and off-machine CMM.

- Edition 2 enables kinematics for digital twin manufacturing.

- STEP has the biggest and most widely tested information model for engineering.

IFC very popular for building models

STEP reduces the cost of manufacturing by allowing products, processes and machines to be assembled digitally for testing before delivery. IFC does the same for building construction.

- IFC technical meetings include thousands of attendees.

- IFC translators are being upgraded for latest STEP geometry.

- Building projects are producting very large multi-gigabyte IFC models.

- Every BIM system has an interface to read and write IFC.

If you own a CAD, CAM or BIM system, then we can help you extend and maintain your STEP and IFC interfaces with the latest libraries and visualization systems. Our librares are used by many of the leading CAD vendors, including NX and Autodesk, because they are the fastest and most reliable.

If your are a leader in manufacturing or construction, then we can help you use STEP and IFC to make better products. We are leading the deployment of 3D product models in manufacturing automation. There are many savings including a reduction in the cost of tooling of 15% or more.